Choosing Tate Andale products is choosing to be a part of a nearly century-old industry mainstay.

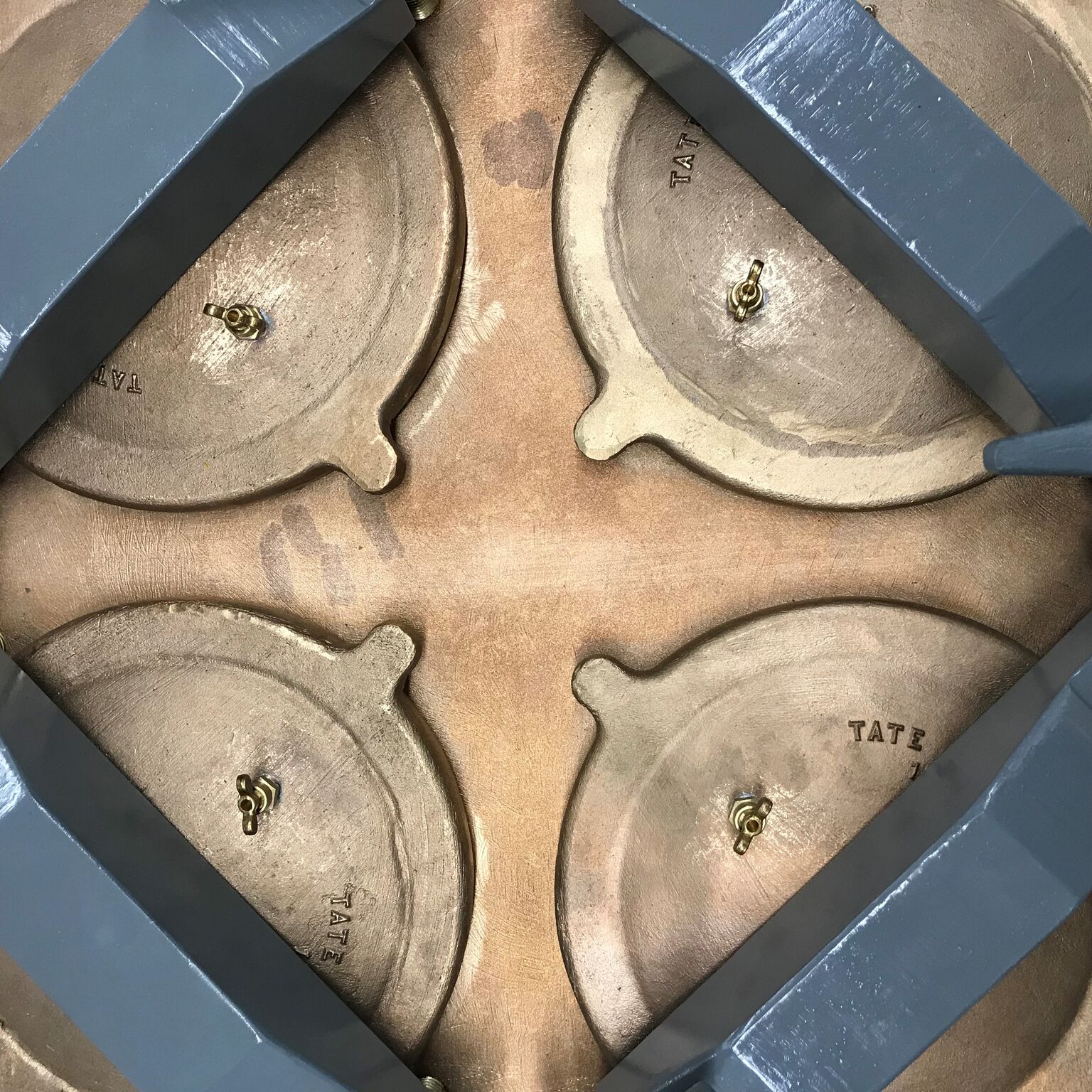

Spanning four generations, Tate Andale industrial equipment are continually chosen by leading manufacturers dependent on product longevity and low maintenance costs. With heavy castings and greater wall thickness, Tate Andale industrial strainers, filters, valves, and heat exchanges stand the test of time.

Our entire staff works together under one roof in Baltimore ensuring that customer requirements do not get lost or mishandled. Tate Andale engineers are well-versed in ASME, ASTM, ANSI, AWS, API, AWWA, ABS, Military, and ISO best practices. Our team has a mastery of the domestic supply chain, and a superb knowledge of CNC and manual machining. Our spacious fabrication shop and assembly area allow us to build complex, large-scale products. Acceptance testing, coating applications and crating are performed on-site, and are the final steps before our premier products are delivered for installation.

Learn more about Tate Andale’s capabilities by following the links below:

- Strainers & Filters

- Custom Fluid Control Valves

- Custom Industrial Projects and Build to Print

- Project Portfolio Page

Our highly capable and flexible team works hard to ensure that failures do not shut down customer processes: Tate Andale products are thoughtfully designed and carefully built to ensure decades of American made dependability. Contact us for more information about our engineered and manufactured solutions.