Commitment To Tate Quality Is Documented In The Field & In The Files

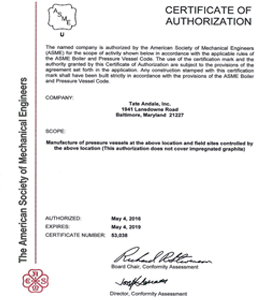

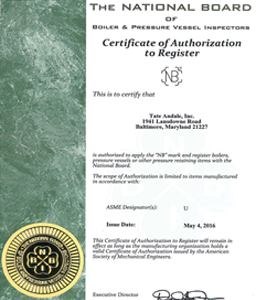

A longer lifespan and lower maintenance costs make our products the best choice for the toughest applications. For nearly a century, industry leading organizations, including the United States Navy, have chosen Tate Andale fluid handling equipment for its long life and low maintenance costs. Tate Andale is certified to ISO 9001:2015, MIL-I-45208, and we carry a U-Stamp. All custom fabricated vessels are manufactured in accordance with ASME Section VIII, Division 1 rules. Tate Andale equipment lasts for decades. With heavy castings and greater wall thickness, our products are so durable that they are found operating in the field over half a century after installation. Our unique design makes servicing quick and easy, reducing downtime, maintenance expenses, and repurchasing costs. Our goal is to provide the lowest life cycle cost with the highest caliber product in the fluid control industry.